We make it easy

Engineered Fire Piping was founded in January 2011, by an experienced team that shares a vision of providing high-quality fire sprinklers pipe fabrication services.

We are located in Yuncos (Toledo) in a well communicated Industrial Area, 44 km far from Madrid. Our Facilities include more than 15.000 m2 of production and coating processes area, and over 30.000 m2 of indoor and outdoor logistic and storage areas.

Our pipe production lines include 6 Robotic Cells and can daily reach the fabrication of the fire protection pipes required for the installation of up to 12000 sprinklers heads. The production area also includes an Automatized Coating Line that produces over 30.000 m of coated pipes daily.

e-Fire Piping offers complete turn-key production services and has become a market benchmark as worldwide supplier of prefabricated pipes for automatic sprinkler systems, having presence in more than 30 countries.

We continuously grow by adding not only new geographic areas to our market but some new high-quality products to our portfolio, including the market recognized water tanks and both, pillar and underground, wet and dry fire hydrants

The increase in billing and expansion at the national and international level, together with the commitment by the VET Directorate allows constant investment in quality material and human resources with high training and professionalism, which allow continuous improvement in: production processes, quality of finished product, competitive prices and capacity to cover large-scale projects.

Innovation by experience

The increase in billing and expansion at the national and international level, together with the commitment by the VET Directorate allows constant investment in quality material and human resources with high training and professionalism, which allow continuous improvement in: production processes , quality of finished product, competitive prices and capacity to cover large-scale projects.

Innovation by experience

Our team works focused on the satisfaction of our clients, valuing the philosophy of excellence in everything we do together with rigor in all processes. Each person works in unison to achieve the success of our clients’ projects.

Our facilities

Engineered Fire Piping has the most modern and innovative technology and production facilities to prefabricate pipes for sprinkler systems.

eFP has a new and unique fully automated robotic system for manufacturing prefabricated pipe lines, where diversification of materials, does not hinder obtaining excellent results.

With the Quality Management System integrated in all the actions of the production processes, Engineered Fire Piping demonstrates its clear business philosophy of customer service, at the highest level.

Facilities

Processes

Precision

Our painting line

It allows to obtain high quality results in a wide range of pipe diameters and colors, with a large production capacity. The versatility of the line and easy change of color allows to execute the painting operation even with complicated mixtures of different diameters and thicknesses.

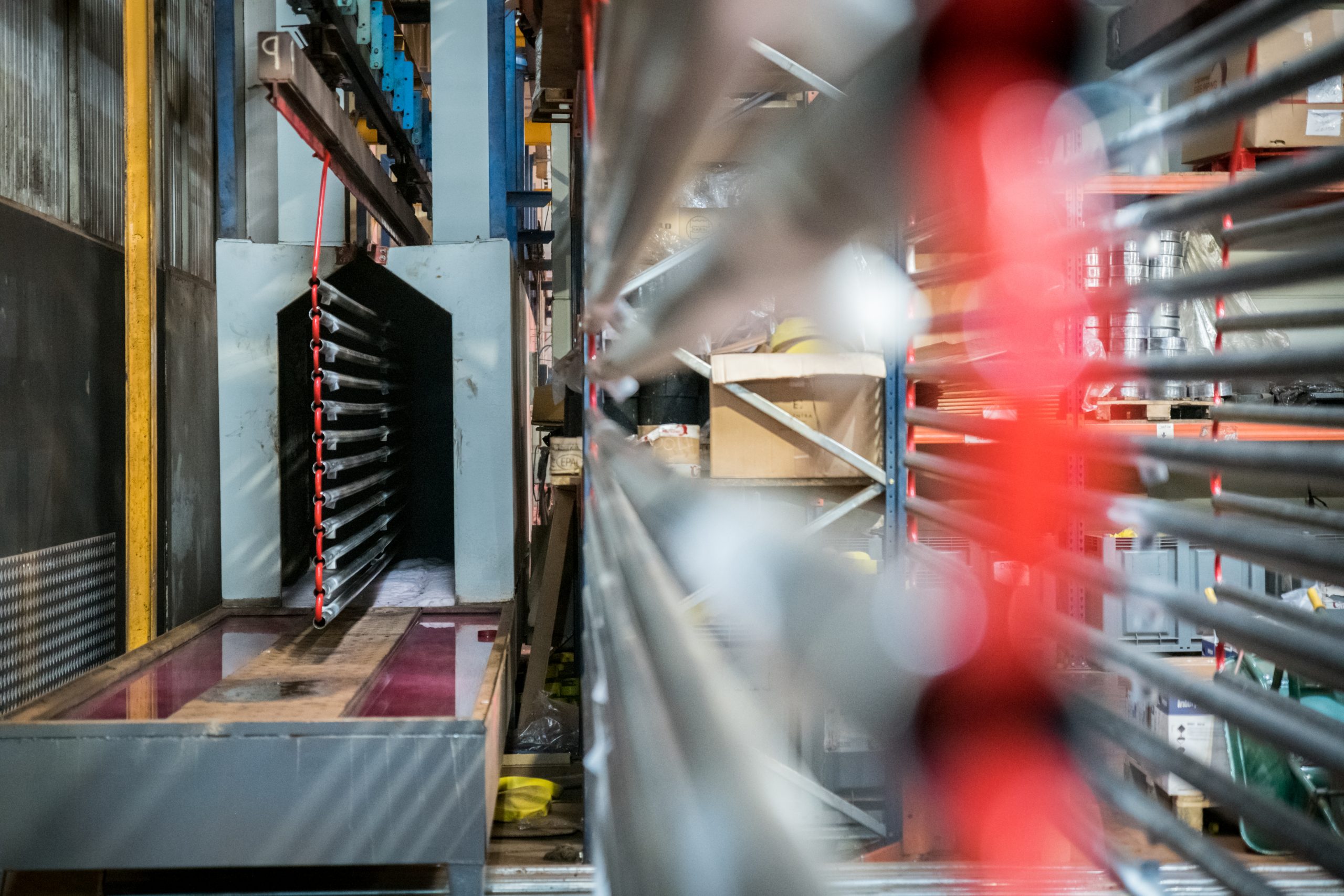

Shoot Blasting line

The first treatment that pipes go through in our factory is metal surface cleaning by shoot blasting, to achieve at least SA 2 ½ according to GRADE EN ISO 8501-1, and a roughness degree of nodular THICK according to standard EN ISO 8503-1. A lifting system guarantees vibration and emptying of the shot within the pipe.

Degreasing and phosphating tunnel

Washing inside and outside the pipe, degreasing and application of amorphous phosphate, which prevents oxidation and corrosion. Blowing drops and stoving 180º.

Cabin for antioxidant primer

Or finishing, liquid application.

Powder paint booth

With electrostatic application and quick color change.

Two ovens

The first for the post-degreasing-phosphating and the second for the polymer powder paint drying.

Robotic cells

Prefabricated long maxima are:

6.00 m for diameter DN25.

9.00 m, for DN32 to DN80.

7.50 m, for DN100 to DN200.

A semi-automatic robotic cell allows prefabrication of large diameter pipes that can reach up to 14 “in complex configurations.

Lines of automatic grooving, and various machinery of manual or semiautomatic use complete our production facilities to cover a wide range of customer demand.

A fast response and agility in our deliveries, differentiate us from our competitors. Our facilities and machinery are constantly evolving and are always ready to give the best results.

In addition to the manufacturing facilities, our logistics and packaging sections, allow to prepare, identify, and package our products according to the specifications of our customers, so that with very dynamic processes, the products are prepared and ready for transport.