Hydraulic PVC Pipe

-

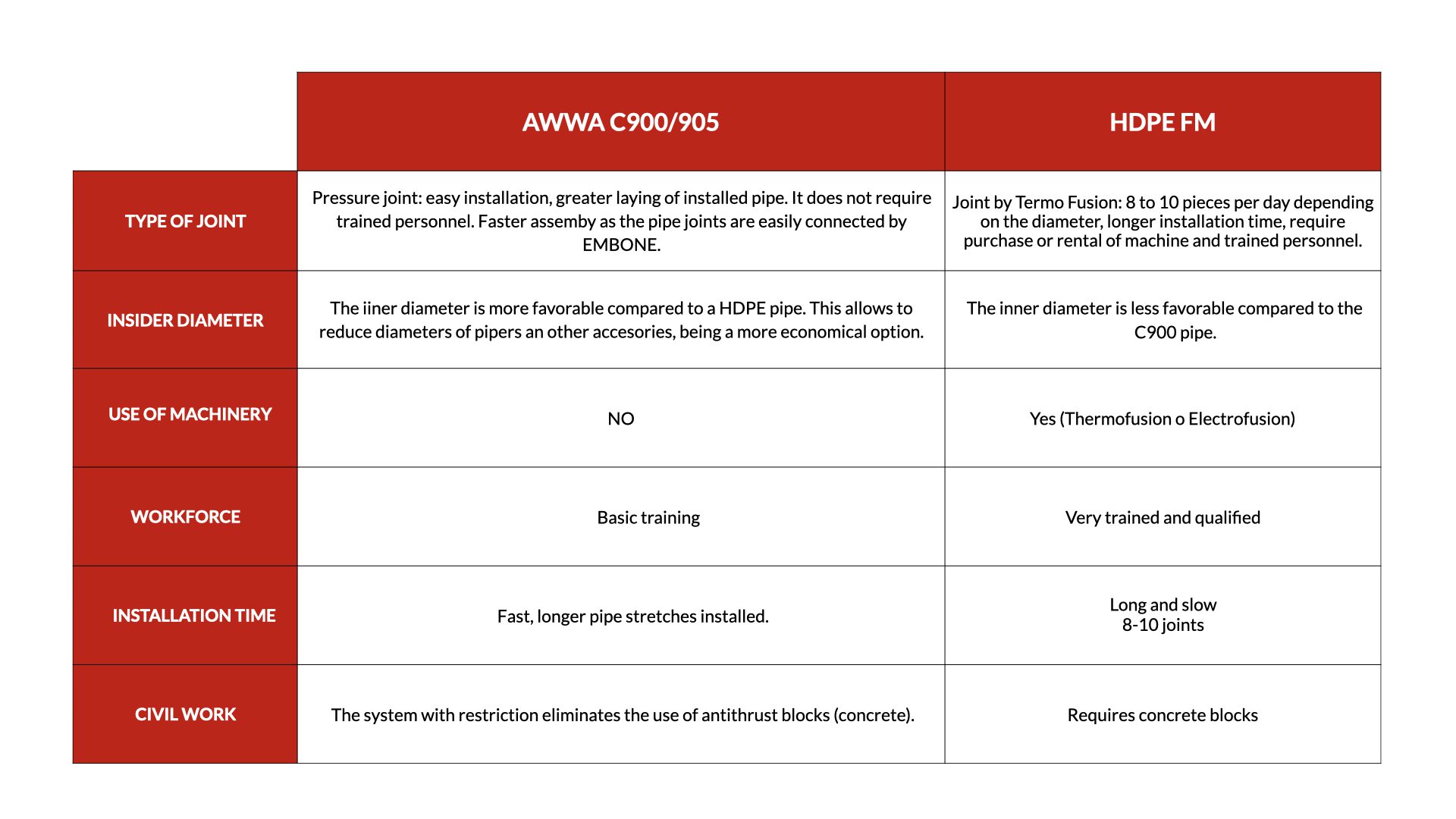

- UL Listed and FM approved for fire protection applications

- Hydraulic advantage (larger internal cross-section)

- 100% mechanical installation. Quick and easy connection (no qualified personnel or machinery required).

- Wide range of accessories is available. No anti-push concrete blocks are required.

- Water-filled pipes repairing is allowed

- Allowed in explosive environments

- Reduced thermal expansion

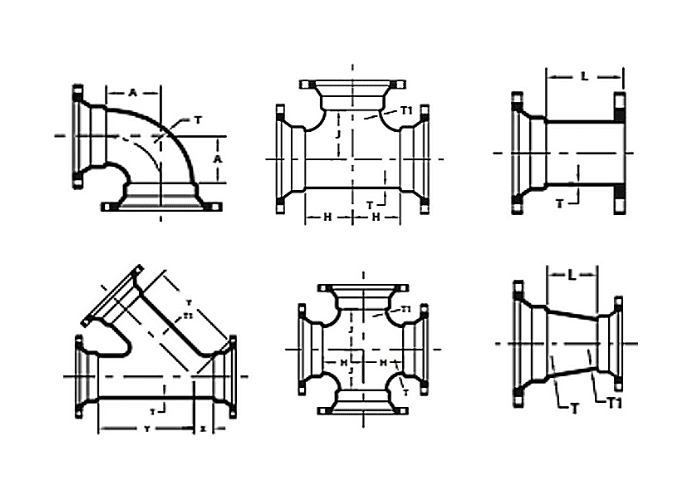

CONNECTION ACCESSORIES FOR PVC PIPES AWWA C900/C905

CONNECTION ACCESSORIES FOR PVC PIPES AWWA C900/C905

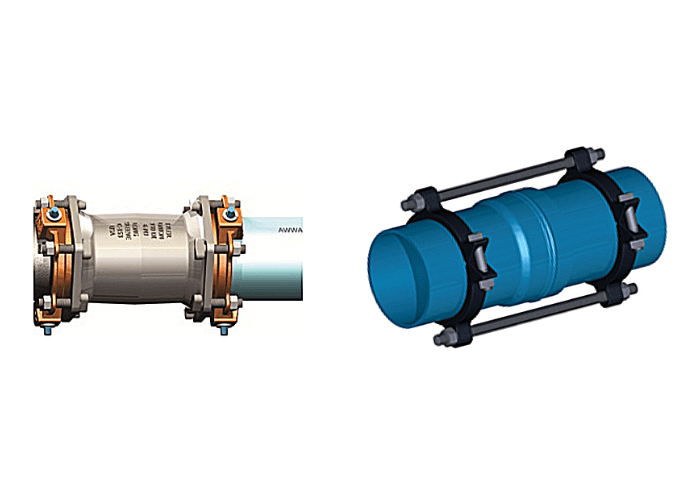

Mechanical anti-push connections and restrictors:

Ductile iron accessories

Joints for internal restriction

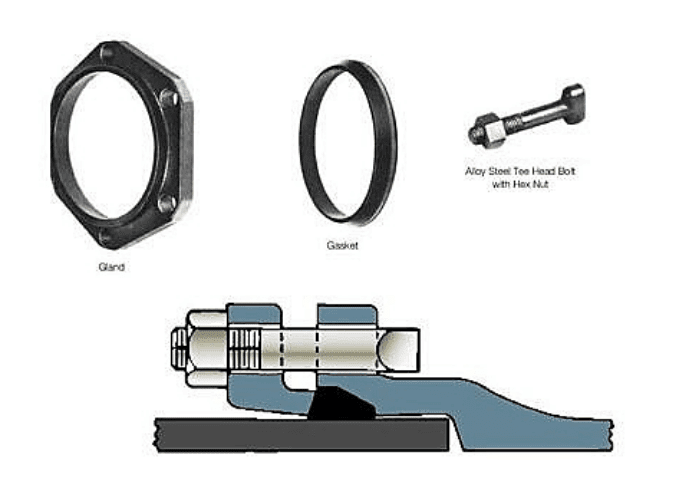

Mechanical joint gaskets

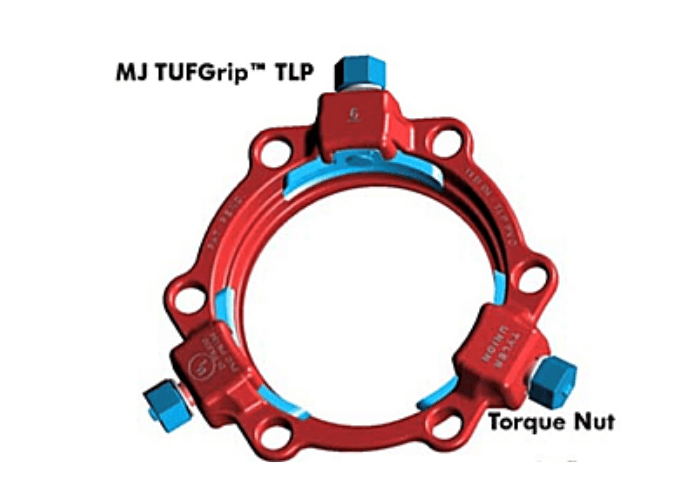

Connections with restraint system

Mechanical joint

What is a PVC Pipe in a fire protection network?

What is a PVC Pipe in a fire protection network?

The pipe is primarily intended for use in transporting potable water in buried installations. The standard describes dimension ratios (DRs) 14, 18, and 25 for nominal pipe sizes ranging from 4 in. (100 mm) through 12 in. (300 mm).

Pipe outside diameters (ODs) conform to those established for CI-equivalent ODs (CIOD). Pressure classes range from 165 psi (1,140 kPa) to 305 psi (2,100 kPa).

The ratio of a pipe’s specified average outside diameter to its specified minimum wall thickness. For US customary units, the specified average outside diameter is used for establishing pipe DR. For SI units, the minimum specified average outside diameter is used.

Fabricated fittings comprise single or multiple segments of PVC pipe cut into wedge shapes, or otherwise prepared to accept leg insertions, and joined under factory-controlled conditions to form an essentially homogeneous structure. Reinforcement may be applied and permanently bonded to the outside surfaces of the fitting.