Carbon Steel Pipe

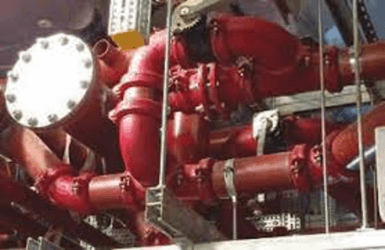

Carbon steel pipe is the most used in the aboveground sections of fire protection installations. Below, we present the most common types of steel pipes, as well as some characteristics linked to their manufacture.

The two most common types of steel pipes used in fire protection:

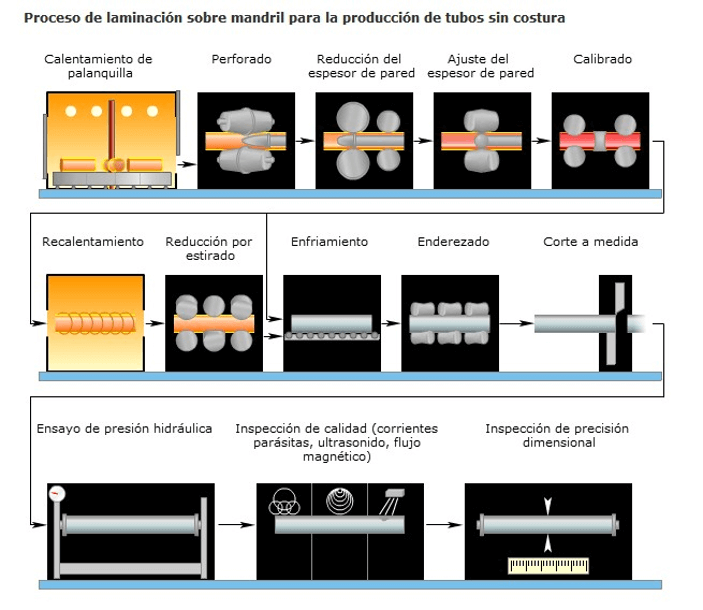

Pipes that are manufactured according to a mechanical deformation process, cold or hot.

- S.S.P. pipe is manufactured from a cylindrical steel ingot that is heated in a furnace before extrusion. During the extrusion it is passed through a cylindrical die and then the hole is made by means of a penetrator

- Existing pipe Standards for seamless steel pipe for fire protection systems are; ASTM A 106, API 5L, EN 10216-1, ASTM A53 S, ASTM A795 S, EN 10255 S

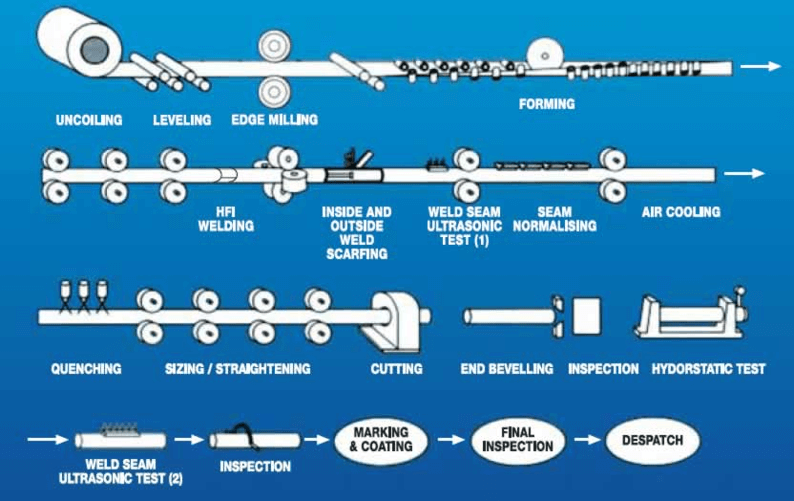

Pipes that are manufactured from a steel strip, of appropriate width and thickness. The welding processes can vary; electric resistance welding (E.R.W.), high frequency welding (H.F.I.) or submerged arc welding (S.A.W.).

Pipes for fire protection systems are longitudinally welded HSW type. Spiral welded pipes are only used for large diameters that are not commonly used in fire protection systems.

- Welded pipe is produced by forming a cylinder from flat steel sheets

coming from a hot strip mill. The welded seam is either parallel to the tube axis or in a spiral direction about the tube centreline. By varying the spacing between the rolls bend radius can change to manufacture different pipe diameters. - Existing pipe Standards for welded steel pipe for fire protection systems are: EN 10217-1, EN 10255 W, ASTM A53 W, ASTM A795 W, ASTM A135.

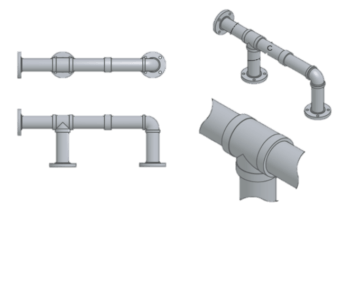

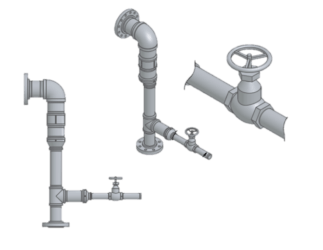

Pipe joining systems

Threaded piping systems are used for small lines, usually of 50 mm diameter and are easily assembled using standard fittings. The removal of metal to create the thread is a disadvantage and fatigue strength is poor. There is no need for coded welders when a screwed pipe system is used except where seal welding is undertaken.

Butt welded piping systems are used for most process, utility or service piping. Butt welding is the most practicable way of obtaining strong, leak-proof joints, especially on larger piping.

The pipe and fittings used have, or are prepared with, standard weld preparation.

They require high levels of workmanship in their assembly and welding.

Socket-welded piping systems are used for lines of small diameter which carry flammable, toxic or expensive materials where no leakage is permitted. They are easier to assemble and weld than butt welds and no weld metal can enter the bore. The pipe end is finished square and fitted into the fittings, usually with a 1.5 mm gap. This gap sometimes pockets liquids and is not recommended if severe erosion of crevice corrosion is anticipated.

Grooved piping system is the most versatile, economical, and reliable joining method for fire protection piping system. The coupling body performs several functions. It contains the rubber gasket and holds it firmly in place for proper sealing. The body also embraces the entire circumference of the end of the pipe, so that it holds them together, but still allows for flexibility. The leak-free joint is made without exposing workers or properties to the effects of fire, smoke and other risks associated with the cutting and welding process.

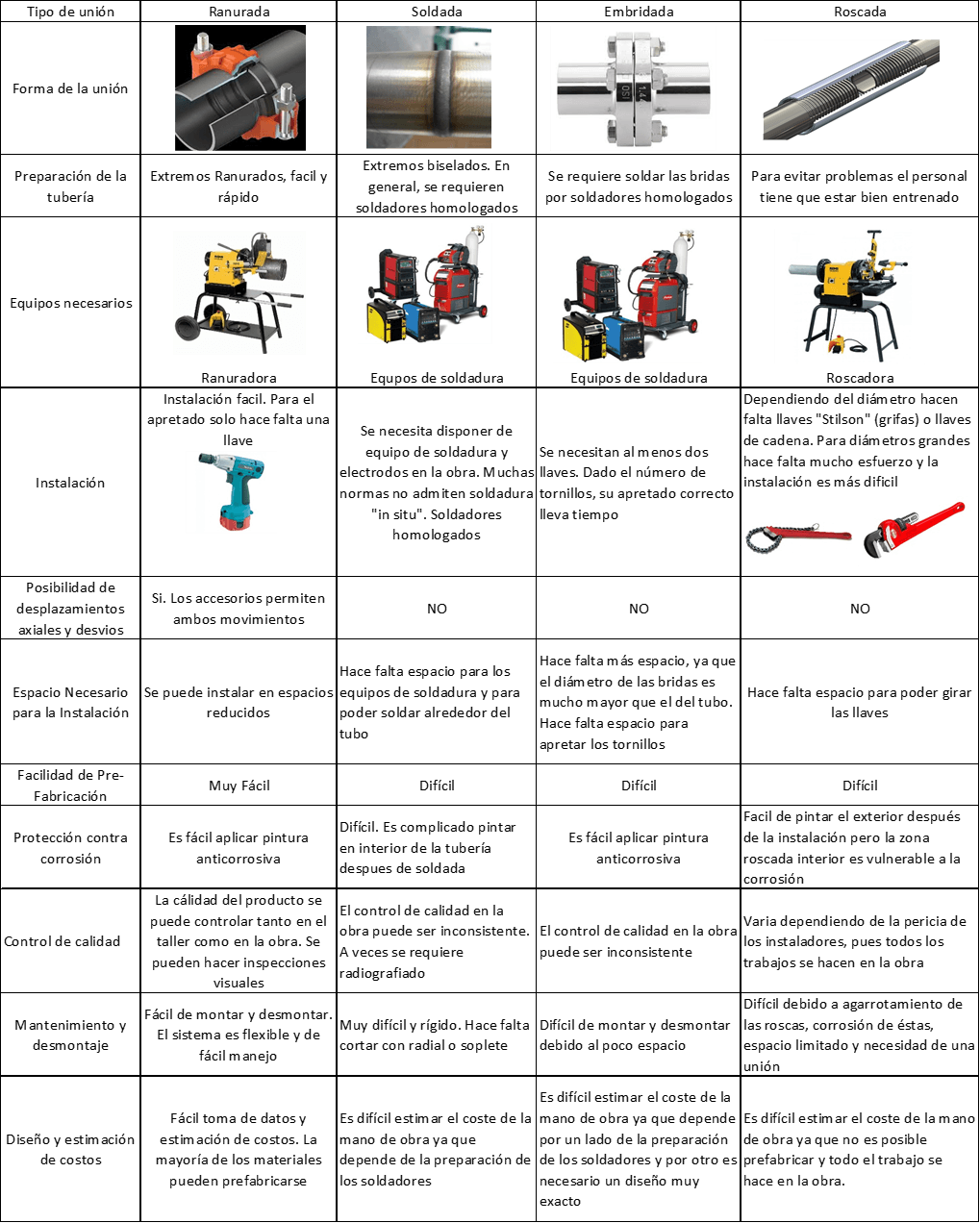

Major pipes joining methods comparation

A comparative table is included with the four mentioned joining. Following systems main characteristics are compared: Pipe end preparation, installation, pre-fabrication possibilities, maintenance and reparation. Both, technical and economics, advantages and disadvantages are included.

After the table analysis we can conclude, that thanks to its specific features, grooved system is the most appropriate pipe joining method for Fire protection Systems.

Pipe end preparation is fast and easy, installation process requires only the fastening of a couple of bolts and nuts, connected pipes are able to allow deflection and axial displacement, a few room is required for installation, so it can be installed in small spaces. Pipe prefabrication process is very easy. Product quality is easily controlled at both, the factory and job site. Installation can be visually checked. Surface protection can be easily applied. No “hot jobs” are required for dismantle or reinstall operations and design and cost estimation could be easily done.

All these features made this joining process the most appropriate for prefabrication, because most of the preparation works can be automatically performed at the factory with a higher performance, less cost and better-quality control. The required number of on-site working hours decrease dramatically and consequentially the total cost of the installation also do it.